After several tests we are pleased to announce to the market that the collaboration with the Berlin company Raindancer has produced more than satisfactory results.

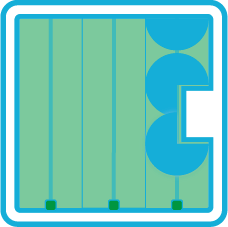

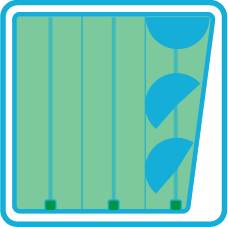

The integration of the jet variable working angle management system Raindancer Sector Control and the OCMIS RAIN CONTROL 5 now allow even better irrigation uniformity and more effective management of changes in the sprinkler working conditions.

The computer that controls the machine then receives the working values directly from the Raindancer system, which in case of changing field conditions, such as the presence of obstacles, irregular fields, etc. etc. If there are different soil conditions on the field, the system can also use application maps for variable rate irrigation. It proceeds to recalculate the exact speed of the sprinkler trolley needed to maintain the amount of water distributed on the ground by sending it autonomously to the machine computer without the help of the operator.

During the work phases the 2 systems exchange the most relevant data for irrigation management such as:

- jet pressure

- actual position of the jet

- real workflow

If the jet displays an alarm, the user can choose whether to receive a warning from the machine or to continue to irrigate by setting different levels of relevance of the alarm occurred.

To have this interconnection system mounted on board your machine you need to be equipped with the package Rain Control 5 and Digital Irrigation. If you have a machine not equipped with this technology, you can always resort to a revamping or an update of the on-board software.